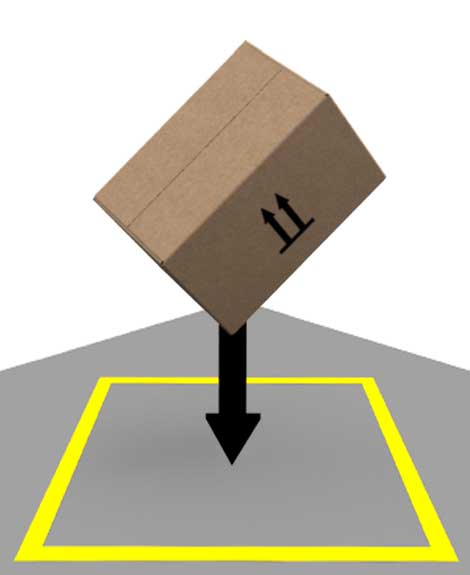

Secure packaging of your dangerous goods

There are numerous legal regulations for the classification, labelling and packaging for the transport of dangerous goods. For example, the outer packaging of dangerous goods must be clearly labelled accordingly. The approval number helps to identify the dangerous substance along the entire transport route. In addition, there is the labelling of the dangerous goods class. The labelling of the dangerous goods requires the shipper to take the appropriate measures so that your cartons arrive safely at their destination and the shipper's employees and the environment are not put at risk.

SHOWROOM

Our service

Klingele offers solutions for the packaging and transport of dangerous goods. In addition to the production and testing of dangerous goods packaging, our service also includes providing advice on the safe packing of dangerous goods. Our test laboratory is a BAM-recognised and authorised test centre for dangerous goods packaging made of corrugated cardboard (4G). We test dangerous goods packaging and take care of the approval.

Testing and approval of dangerous goods packaging

- Approval for dangerous goods in accordance with the 4G / 4GV specification

- Issuing individual approvals

- A variety of types available

- Packaging groups I–III*

- Foundations for packaging drop tests up to a maximum of 80 kg

* The more dangerous the packaged goods are, the safer and more reliable they have to be packed and secured for dangerous goods transport. Packaging groups have therefore been defined to which substances are assigned depending on their degree of danger.

- Packaging group I: Substances with a high degree of danger

- Packaging group II: Substances with a medium degree of danger

- Packaging group III: Substances with a low degree of danger

Your dangerous packaging goods process

- Let us know the 4-digit UN number of your dangerous material, the desired packaging size, packaging design, the adhesive tape used and the filling weight.

- In some cases, the dangerous materials only pose a low risk. In this case, it is possible to ship the goods without an approval in compliance with the law (e.g. LQ - limited quantities). This limited quantity as laid down in the ADR/RID and IATA regulations* provides a partial exemption from the transport regulations.

* Dangerous goods regulations for road, rail and air transport.

- There are different packaging requirements in order to comply with the ADR/RID and IATA regulations.

- These regulations give rise to a selection of packaging material.

- The stability of the packaging is mainly dependent on the thickness of the corrugated cardboard and the technological values of the paper used.

- In all cases, it is mandatory to comply with the Cobb 1800 value. It indicates the water absorption of the outer sheet and is primarily maintained with Kraftliner paper.

- In some cases, the packaging can be shipped as a limited quantity or integrated into one of our packaging type approvals (4G/4GV). A new approval is not required in either case.

- We create an individual packaging solution for you if a suitable packaging type is not available.

- We will be happy to send you samples if a packaging solution is produced to suit your requirements and in accordance with the stress tests.

- Our dangerous goods test centre is approved by the BAM for 4G dangerous goods (cardboard boxes) in class I, II and III up to a weight of 80 kg and a drop height of 1.8 m.

- This means that we have the necessary equipment in our test centre to generate the full range of test reports.

- Dangerous goods packaging undergoes many tests in this regard that have to be passed before the packaging can be used. These include material tests, drop tests and three 24-hour stacking tests.

- The adhesive tape that is used is an important factor. The width and the tensile strength, amongst other things, are specified in the test report and approval.

- If several packaging solutions are needed for your product, these do not necessarily require individual approval. Often it is possible to combine them in a packaging range – we need to check this in individual cases.

- As soon as the test report is completed, this is forwarded to the relevant authority. It grants your individual approval number.

- On the day after the production of your dangerous goods packaging with its individual approval number and labelling, it still undergoes the manufacturer's series control for the final approval.

- The packaging that has been produced is rigorously checked one last time.

- If all specifications have been met, your packaging is approved and the finished products are delivered to you.