Eco-friendly Products and Solutions

* Pflichtfelder

Diese Angaben sind zur Anmeldung zum Newsletter "Packendes" notwendig.

Energy and resource efficiency are key considerations in our production processes. We are also committed to high standards of sustainability when developing new products and solutions. What we offer you today:

Corrugated board packaging is made entirely of sustainable raw material; it is manufactured from windfall timber and thinnings, or recycled material such as waste paper, boxes or used corrugated board. Adhesives made from sustainable raw materials such as corn, wheat or potato starch are also used. Corrugated board is a genuine natural product and the number 1 packaging material for environmental compatibility!

Corrugated board is also 100 percent recyclable; after use, the packaging is returned to the manufacturing process via waste paper. In Germany, corrugated board packaging is almost completely recycled, thus fulfilling the key requirements for an ecological closed-loop product. In addition, corrugated board is biodegradable, unlike plastic. After multiple recycling passes, used paper fibers are discharged from the production process, they can be used for energy generation or composting.

Our corrugated board packaging is made of 90 percent recycled paper. The remaining ten percent comes from sustainable forest management or controlled sources. We therefore believe in the importance of a transparent supply chain. Here you will find an overview of certified paper mills and corrugated board plants.

The FSC® (Forest Stewardship Council) is an independent, non-profit, non-governmental organisation that promotes the responsible management of forests. It has defined appropriate environmental and social standards whose scope also extends to recycled material such as paper. The FSC® certificate is the best-known standard and is now widely accepted internationally. Certification of our plants provides proof that we only use recycled paper or paper from responsible, controlled forest management throughout our entire value chain. Our paper suppliers are of course also FSC® certified.

According to the German Packaging Act, we are obliged to take back transport packaging, within the scope of § 15 paragraph 1 sentence 1 of the German Packaging Act, free of charge at the place of actual receipt or in its immediate vicinity. If this is not possible, you have the option of returning the packaging to us.

Customer benefits and protection of the environment are always in the forefront of our packaging development process. We continuously strive to improve our packaging concepts with regard to the use of material and natural resources - and also develop new solutions with innovations such as D flute and FastFix, or special packaging designs for specific sectors. The aim is always to achieve an optimum blend of excellent product protection, careful use of natural resources and cost efficiency.

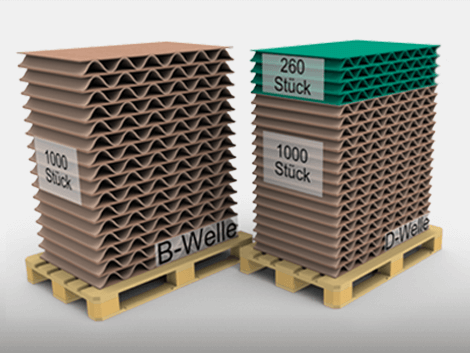

D flute is an eco-friendly and economically-attractive alternative to B flute: it is thinner and enables up to 26 percent greater pallet capacity. This reduces handling, logistics costs and the carbon footprint. It offers an excellent printing surface for a brilliant image thanks to its narrow flute pitch - an optimum showcase for your products!

FastFix is an eco-friendly solution popular with users: the concept consists of a corrugated box made of recycled paper and an insert of flexible depth from the same material, which secures goods in place during transport. Packing material, such as plastic chips, bubble wrap or similar, is no longer necessary - a huge bonus for the environment!

Resource efficiency, product protection and effective advertising: our single-shipment packaging for glass bottles ensures that valuable products can be shipped safely without a thought! This concept received a World Star Award in the drinks category from the World Packaging Organisation (WPO)!

The corrugated cardboard WellBag is made of 100 percent sustainable raw materials. In terms of its LCA, the WellBag reusable tote scores much higher than paper bags, cloth bags and all bags or carriers made of plastic. It is compostable and thanks to its trendy design, presents an attractive carry bag for your customers.

All sites of our group of companies are certified to BRCGS/IoP as we consistently comply with the highest possible standards in hygiene and product safety. This ensures that there is no avoidable risk of contamination from our products or production environment.

The BRCGS IoP was developed by the British Retail Consortium (BRCGS) in cooperation with the Institute of Packaging (IoP). It is an internationally-recognised quality assurance standard for primary packaging and food packaging. Its core elements include topics such as risk and hazard management as well as quality and hygiene management.

We have acquired considerable knowledge and experience in technology, logistics and other topics since our company’s inception, 100 years ago. You too can benefit from this know-how – at our Klingele Academy!