Success Story

Automotive parts trade

in E-commerce

* Pflichtfelder

Diese Angaben sind zur Anmeldung zum Newsletter "Packendes" notwendig.

High cost at high throughput times: the products are delivered to different pick stations by the conveyor and are packed into a box by the employees. In the meantime, the box is filled and sealed at the top and bottom with adhesive tape. The box is then labelled, glued on by a machine, strapped and moved to the outgoing goods area.

Our packaging experts analysed the existing packaging and explored alternatives. The Klingele machine advisers made an inventory of the existing machines and facilities.

New packaging design with additional flutes on the slot-in base enable the box height to be adapted.

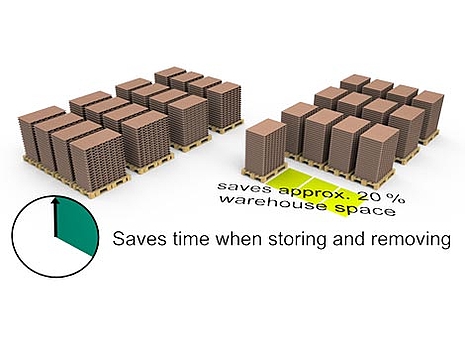

Testing of the load requirements on the packaging and a reduction in the grade composition from BC-flute (with 7 mm) to EB-flute (4.5 mm) and from B-flute to D-flute.

Advice on the selection of the optimum packaging and material combination as well as on the implementation.

Online retailer for automotive spare parts, accessories and care products with over 700,000 car parts.